The Lean concept is often associated with manufacturing where waste, its elimination and continuous improvement is concerned. Recently, I have learned more about how the concept is being applied to organizations of all types and am left thinking how this can be applied at Remedi...for and with our clients.

Our desire for continuous improvement has always been a core value since the founding of our company in 1994, it's what we do for our clients. We have found many that believe, "good is the enemy of best". But seldom do organizations and their associates take it to the level of those in REAL pursuit of Lean.

So how might Lean concepts apply to Integration?

This is what I kept wondering when touring the manufacturing facility of a friend implementing concepts of Lean from the book "2 Second Lean". While working our way through his facility on a "walk and talk" one Wednesday morning (a weekly event for this organization) we learned of process improvements that had been made by his team in the prior week. People were excited to share their process changes with those in the organization. It was noted that some of these changes provided significant time savings over long standing processes.

Given the variety of process changes some were manual improvements that had been made, others were manual processes that had been automated by systems and technology. One such improvement was the prerequisite to beginning an integration project where data from a shop floor product testing device would be sent to their CRM system so results could be stored and attached to shipment and invoice documents.

In writing this piece it dawned on me that all of our integration projects are Lean initiatives where waste has been identified and stands to be reduced or eliminated in the course of the project. EDI, B2Bi, MFT, EAI, middleware, and supply chain folks are all involved with Lean and may not even be aware of it. Think of the possibilities if we are educating and advising our line of business and business network of partners and developing integration solutions with Lean in mind?

If we as Integrators have been doing it all along, the Lean premise of continuous improvement supports that we should learn more so...

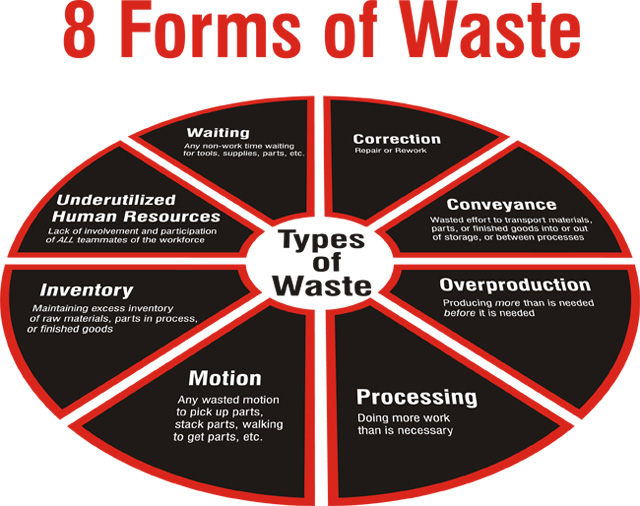

There are 8 types of waste, based on the description of each you can spin their applicability to integration opportunities and the processes we often automate...

Here are some excellent sources that might help you apply Lean concepts to your integrations, the stakeholders these integrations support, and improvements that can be made in your integration processes that reduce manual processes, error resolution/prevention, or cycle time to accomplish objectives.

Stay tuned for future Blogs about Lean and its application to integration as we have just begun our journey...